To support its operations, Atlas Copco wanted to implement HVO and AdBlue at its headquarters in Boom, in the province of Antwerp, where 300 to 400 fleet units park regularly.

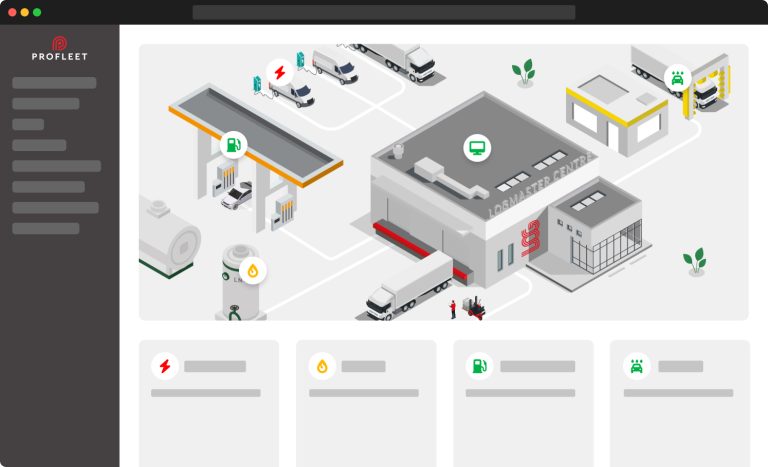

‘For many years, we relied solely on traditional fuel to power our diesel-driven units. But with product innovation, new engines, new technology and our commitment to sustainability, we started using HVO, which is green diesel, and AdBlue,’ says Stephan Van Bosch, Atlas Copco’s Logistics Manager in Boom. He is responsible for coordinating the rental operations and explains the cooperation with Profleet and TSG in detail. ‘Suddenly we had to handle three different liquids in our depot,’ he adds.