RBS

RBS and BSU rely on LOGmaster for modern and efficient portfolio management.

RBS and BSU rely on LOGmaster for modern and efficient portfolio management.

TSG Switzerland SA has systematically expanded and modernized the depot infrastructure at the companies Regionalverkehr Bern–Solothurn (RBS) and Busbetrieb Solothurn und Umgebung (BSU) over several years.

With intelligent, scalable depot management solutions for refueling, charging and washing, the Worblaufen (BE) and Zuchwil (SO) locations have been made future-proof, efficient and ready for the mobility of tomorrow.

Thanks to our ProFleet solution, RBS/BSU now has a central, cloud-based system at its disposal, providing maximum overview, efficiency and future-proofing in depot operations.

RBS and BSU together operate 4 railway lines and 29 bus lines in the Bern-Solothurn region, transporting around 32.5 million passengers annually. With over 630 employees, they offer reliable and sustainable mobility for both commuters and leisure travelers.

The focus is clearly on the future: RBS and BSU are gradually converting their fleets to electric buses and service vehicles. The goal is to electrify the entire operation by 2040, thus making an active contribution to the long-term sustainability strategy.

In June 2025, BSU and Busbetrieb Grenchen und Umgebung (BGU) decided to merge to form Busbetrieb Solothurn Grenchen und Umgebung AG. This is another important step towards pooling resources and strengthening mobility in the region for the long term.

Managing two depots, Worblaufen (BE) and Zuchwil (SO), with different energy sources such as diesel, AdBlue and electricity, as well as bus washes, presented the operators with growing challenges.

Both locations operated with isolated solutions, which made data maintenance difficult, led to ambiguities in the operational process, and limited the overview of all processes.

Previously, we had several separate systems in use that didn’t communicate with each other. This made administration considerably more difficult, especially regarding data security, analysis, and transparency.

To meet these challenges, we implemented the LOGmaster depot management system, a holistic solution for multi-energy operations at multiple locations.

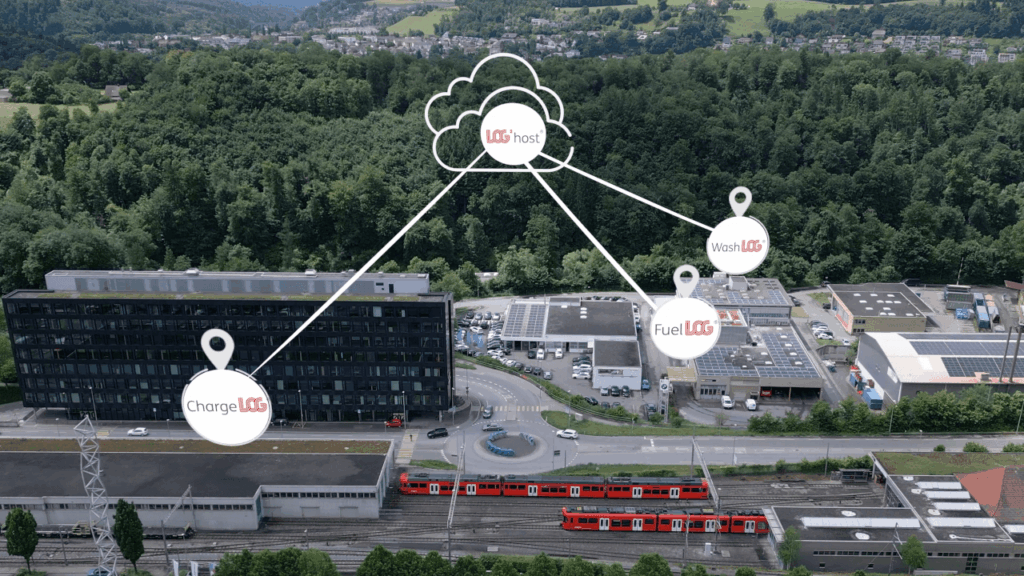

Over the years, FuelLOG, ChargeLOG and WashLOG terminals have been installed at the two locations in Worblaufen and Zuchwil and intelligently networked together via the cloud-based platform LOG2host.

This allows the depots to be operated today as a centrally controlled system, with a uniform database, location-independent access, and increased operational stability.

FuelLOG

Efficient management of diesel and AdBlue with adjustable restrictions to prevent errors.

ChargeLOG

Clear, brand-independent monitoring of charging processes for electric vehicles.

WashLOG

User-friendly control of the vehicle wash including program selection, user management and automated reports.

LOG2host

Central cloud database with robust master-slave architecture for reliable multi-site operation.

The ProFleet system enables comprehensive control of all depot processes . Every function is controlled via specially developed terminals that are fully connected to a central cloud database.

Vehicles and drivers are reliably identified via secure RFID tags . All relevant data is centrally recorded in the cloud and can be directly linked to the RBS/BSU ERP system. This enables transparent allocation of operating costs at any time.

The major advantage is that we can now control all devices from different manufacturers centrally via a single platform. All relevant data is available at all times, regardless of our internal network. Interface problems are a thing of the past.

Since the introduction of LOGmaster, all operational data at RBS and BSU are centrally recorded, accessible at any time, and available independently of the internal IT infrastructure. The new solution not only reduces day-to-day complexity but also significantly minimizes potential errors and maintenance efforts.

At the same time, it creates the necessary transparency for reporting, ERP integration and tracking sustainability goals.

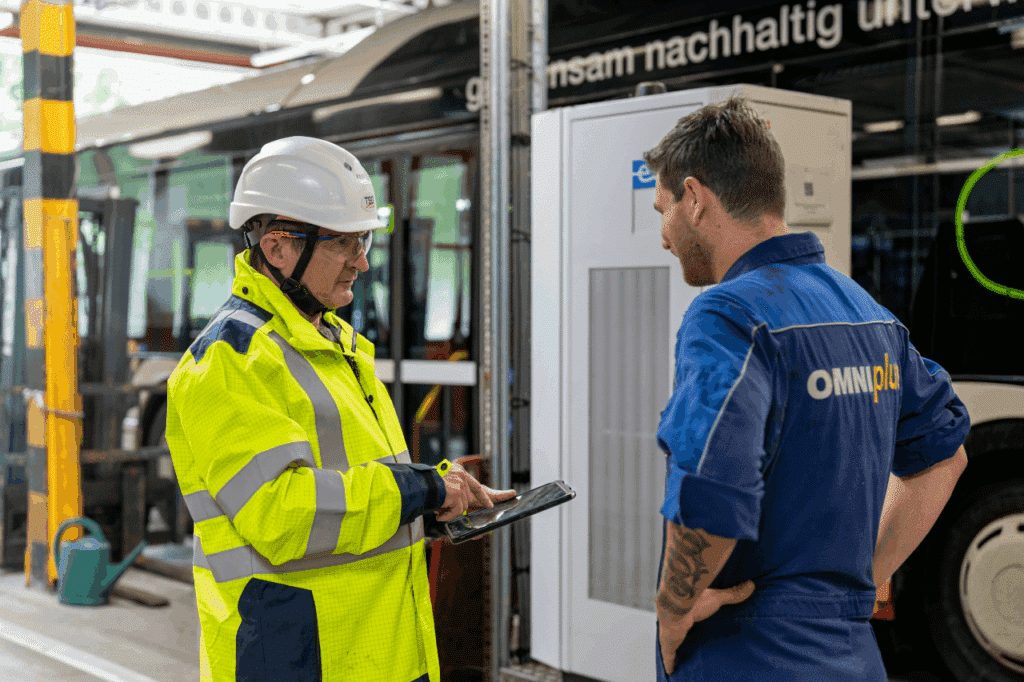

Hardware installation

Assembly and integration of all ProFleet terminals and the tank technology at the two depot locations.

Software deployment

Implementation of the LOG2host platform for controlling and monitoring charging, refueling and washing processes, including detailed reporting.

Maintenance & Support

Ongoing support, remote maintenance and technical support for consistently reliable operation.

Work smarter, not harder. LOGmaster allows you to manage all depot equipment from one place.